Organizing closets efficiently is an important aspect of maintaining a tidy home. One product that has become increasingly popular is the Multiple Space Saving Closet Coat Hanger Hooks. These hooks provide additional hanging space for coats, jackets, bags, and accessories while the use of limited closet space. The manufacturing process for these hooks requires careful attention to material selection, design, functionality, and quality control. Understanding these considerations helps explain why well-made hooks are both durable and practical.

The consideration in manufacturing Multiple Space Saving Closet Coat Hanger Hooks is the choice of material. These hooks must be strong enough to hold multiple garments without bending or breaking. Common materials include stainless steel, aluminum, high-quality plastics, and reinforced alloys. Stainless steel is favored for its strength, corrosion resistance, and polished finish. Aluminum offers lightweight strength, while durable plastics provide flexibility and a smooth surface to protect clothing from snags. Material selection affects not only durability but also the appearance and overall feel of the hooks, which is important for consumers who want both functionality and style.

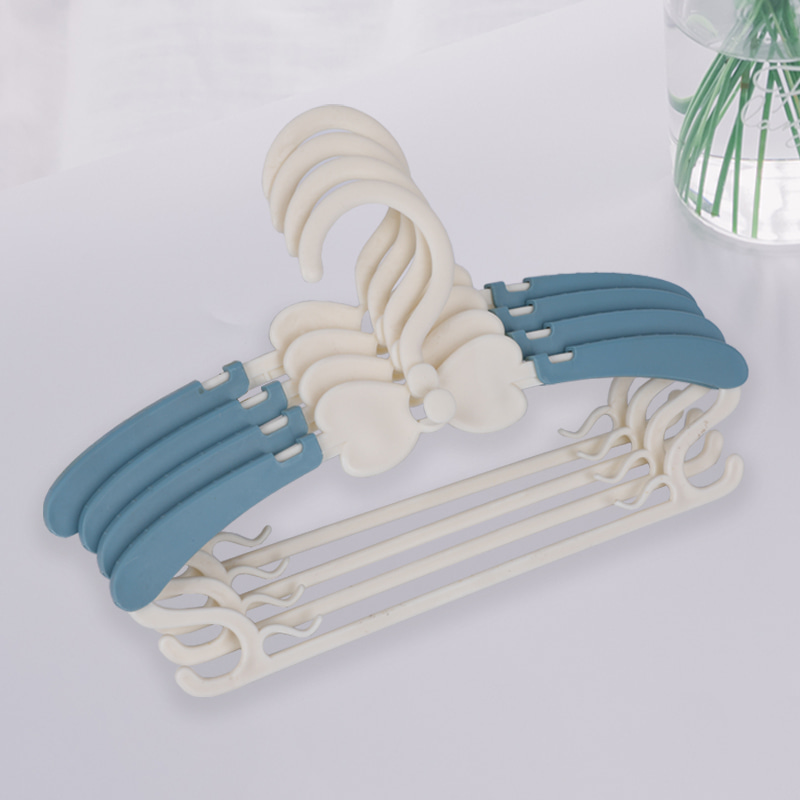

Design is a critical aspect of producing Multiple Space Saving Closet Coat Hanger Hooks. The hooks must be shaped to hold garments securely while preventing slipping. Many designs feature multiple tiers or staggered arms, allowing several items to be hung in one vertical space. Rounded edges or coated surfaces are often included to prevent damage to fabrics. The spacing between hooks is carefully calculated to accommodate different types of clothing, from heavy coats to lightweight scarves, ensuring that each garment has enough room. Additionally, the overall aesthetic is considered to make the hooks visually appealing in a closet setting.

The manufacturing process of Multiple Space Saving Closet Coat Hanger Hooks varies depending on the material. Metal hooks are usually formed through processes such as casting, stamping, or bending, followed by polishing or coating for a smooth finish. Plastic hooks are often produced through injection molding, which allows for consistent shape and precise dimensions. For both materials, finishing steps such as powder coating, painting, or plating enhance durability and appearance. Each step in the process is carefully controlled to maintain the structural integrity and functionality of the hooks.

Another key consideration in manufacturing Multiple Space Saving Closet Coat Hanger Hooks is ensuring they can bear weight safely. Hooks are tested to hold multiple garments at once without bending or detaching from their mount. Stress tests are conducted to simulate real-world use, checking the hooks' performance under different weights and pressures. Reinforced mounting points and well-distributed hook designs increase stability and prevent damage to both the hook and the wall or closet rod it is attached to.

Functionality is central to the design and production of Multiple Space Saving Closet Coat Hanger Hooks. Hooks are designed to be easy to install, often including clear mounting instructions and compatible hardware. The spacing and height of hooks are optimized for accessibility, allowing users to hang and remove garments without difficulty. Some designs feature swivel arms or adjustable positions, providing extra flexibility in how space is used. Ergonomic considerations ensure that the hooks are practical and user-friendly for daily routines.

Quality control is a final but crucial step in manufacturing Multiple Space Saving Closet Coat Hanger Hooks. Finished hooks are inspected for uniformity in shape, smoothness of surfaces, and strength. Hooks are checked to ensure they meet safety standards, carry the intended weight, and do not have sharp edges that could damage clothing. Consistent quality control ensures that every product performs reliably and meets consumer expectations for durability and convenience.

English

English 中文简体

中文简体

Phone

Phone

Email

Email