Bathroom plastic towel racks are common household items that provide practical solutions for keeping towels organized, dry, and accessible. Their production involves a sequence of steps that combine material selection, design, manufacturing techniques, and quality checks. Each stage plays an important role in ensuring that the final product is both functional and suitable for daily use.

Material Selection

The stage in producing bathroom plastic towel racks is selecting the right plastic material. Plastics such as polypropylene (PP), acrylonitrile butadiene styrene (ABS), and polycarbonate (PC) are often chosen because of their durability, resistance to moisture, and ability to maintain shape under regular use. The chosen plastic must be lightweight, easy to mold, and resistant to wear in a humid environment like a bathroom. The selection process also considers color options, since bathroom towel racks are often designed to match different interior themes.

Product Design

Once the material is determined, the design process begins. The design stage focuses on functionality and practicality. Designers consider dimensions, the number of bars or hooks, and the spacing required to allow proper air circulation for drying towels. A bathroom plastic towel rack may include additional features such as a shelf, a swivel arm, or a folding structure. The design also ensures that the rack can be easily mounted on walls or doors. Computer-aided design (CAD) software is often used to create precise models that allow engineers to test the strength and balance of the rack virtually before moving to the next step.

Mold Making

After finalizing the design, the next step is mold making. The mold serves as the template into which melted plastic will be injected to create the parts of the towel rack. Mold production requires high precision, as even minor inaccuracies can affect the final product. Steel or aluminum is commonly used for molds because of their durability and ability to withstand repeated use in manufacturing. The mold includes cavities that reflect the shape of each component, such as bars, brackets, or hooks.

Injection Molding

Injection molding is the primary method used to produce bathroom plastic towel racks. Plastic granules are heated until they melt into a liquid form, which is then injected into the mold under high pressure. The plastic fills the cavities of the mold and is allowed to cool until it solidifies. This process creates strong, uniform parts with consistent dimensions. The speed and efficiency of injection molding make it well suited for mass production of towel racks.

Assembly

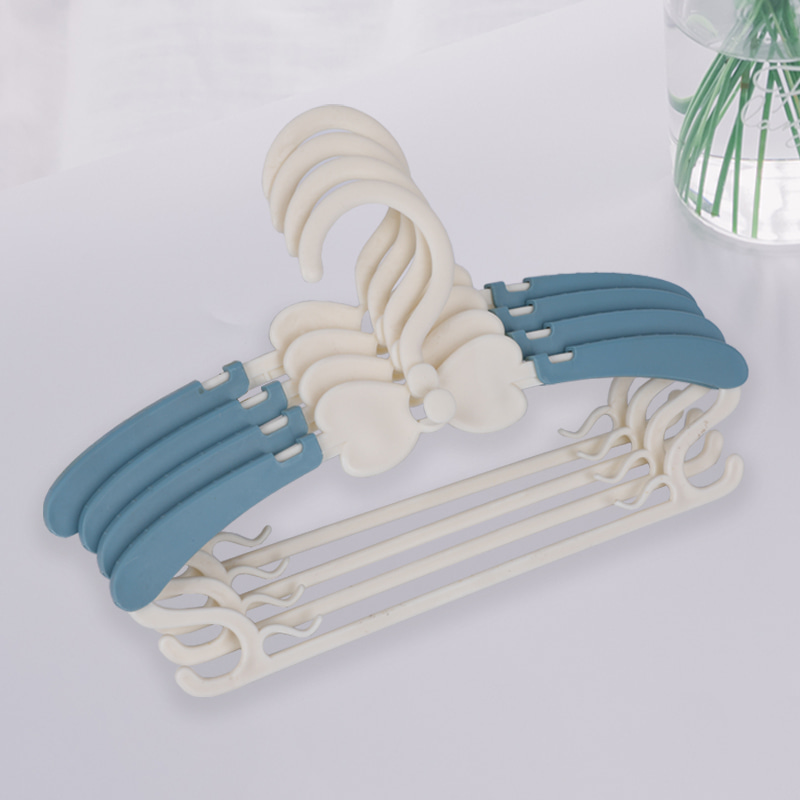

Once the molded parts are produced, the next stage is assembly. Some bathroom plastic towel racks are made from a single molded piece, while others include multiple components that must be connected. For racks with extendable arms, folding sections, or detachable shelves, screws, clips, or snap-fit connections are used to secure the parts together. During this stage, attention is given to ensuring that moving parts function smoothly and that the overall structure is stable.

Surface Treatment and Finishing

To improve the appearance and durability of bathroom plastic towel racks, surface treatment is applied. Some racks are polished to create a smooth finish, while others may receive a matte texture for a different aesthetic. Certain models also include coatings to enhance resistance to water stains or to add decorative elements. Colors are either incorporated during the molding process with colored plastic granules or applied afterward through painting or printing.

English

English 中文简体

中文简体

Phone

Phone

Email

Email